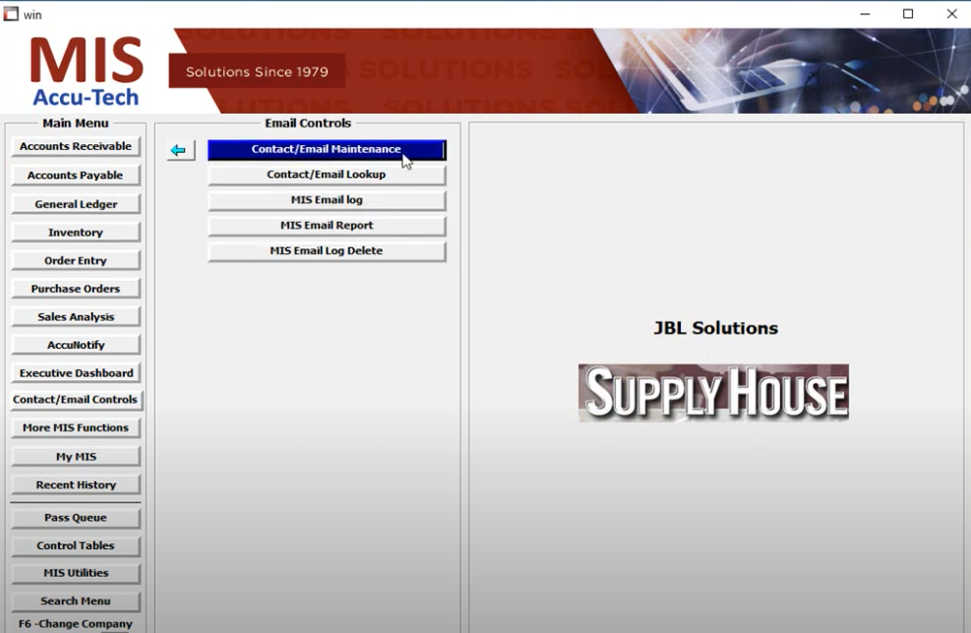

The MIS Assemble and On-The-Fly Assemble modules are integrated with our Inventory and Order Entry functions and allow you to enter component products in order to form a finished product. In general, there are three types of product assemblies (or kits) that are performed in a typical business.

- Pre-Defined Assemblies: These fabricated items are generally standard and typically not associated with a particular order/sale. For example, if you wish to build twenty 6” x 20’ Tow/Recovery straps for stock, you would use this function. The MIS Assemble module allows you to pre-define an assembly formula and automatically remove the component materials that are used in the finished good.

- On-The-Fly Pre-Defined Assembly: These assemblies are generally performed one at a time, often while the customer is waiting. For example, you may not stock (keep on the shelf) a 12”x30’ Tow/Recovery Strap and choose to only fabricate this item when it is ordered by a customer. The MIS On-The-Fly Assemble option allows you to access the pre-defined assembly formula while entering sales orders. You may access the formula and accept or change the assembly. The pre-defined on-the-fly option is also very useful when most of the items will remain the same, but a product needs to be added or substituted for another product.

- On-The-Fly Custom Assembly: These assemblies are based upon customer specifications and the formula is entered "on-the-fly" by the inside salesperson.

MIS Assemble

The MIS Assemble package is integrated with the MIS Inventory module and allows you to assemble and disassemble products for your stock. The formula can contain products, machines, work centers and labor amounts. You can enter “Trial assemblies“ and the component materials requirement report will answer the "Do I have enough stock to build?" question. Component materials can be removed from a user specified location (warehouse) and placed into a different location. The system will automatically remove the component materials from the on-hand quantity and optionally update the costs of the finished product.

On The Fly Assembly

Many businesses provide unique assembled products to their customers. In many cases, the basic components may be the same but lengths, quantities or types will vary by customer. In some, each assembly may consist of a unique set of component products. The MIS "On the Fly" Assembly Module allows for the entry of these custom assemblies.

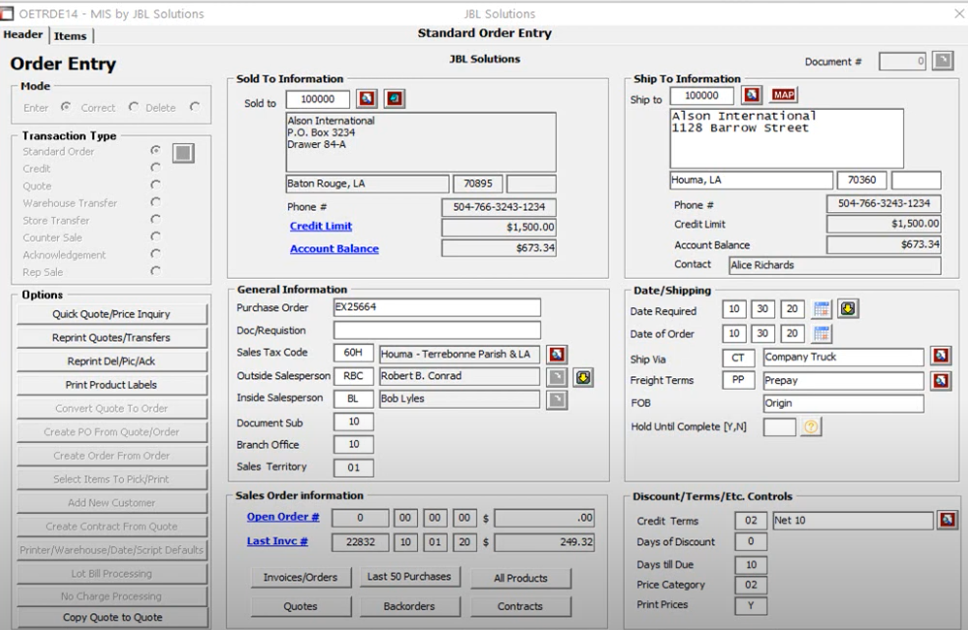

An end product is assembled from the component products you have defined in the MIS Inventory

system. You are given the option to assemble a product at the product prompt during order entry.

Once you select the assemble option you are prompted to enter information about the end product (quantity ordered, unit price, comments, etc). After entering the end product information, you are prompted to enter the component products that make up the assembly.

Spool/Reel/Lot Tracking in MIS Assemble

The MIS Assemble modules support the allocation and tracking of Reel/Spool/Lot ID’s.

Typical Uses of MIS Assemble

- Wire Rope/Slings/Rigging

- Rubber Products (Hoses, Belts, Gaskets, etc.)

- Valves/Fittings/Pumps/Motors/Filters

- Hydraulics

- Electronics/Electrical

- Repairs (when you choose not to show the items used in the repair)